Easy greasing of top bearings via low level greasing points

Easy greasing of top bearings via low level greasing points

Full width floor slats clear the entire floor area, eliminating the possibility of bridging, a problem sometimes encountered with multi chain and slat floor systems. The “socket fit” design allows for easy maintenance which can be carried out in the field, it also allows the chain to pull straight should a slat become bent

16mm, grade 80, heavy duty chains are drawn by high tensile sprockets, which are fitted to the front shaft as well as the driven rear shaft, ensuring perfect alignment and timing of the chains. Each chain has a 32 tonne breaking strain certificate. The same specification chain is used throughout the Mk4 range

The robust one piece SRT 8 gearbox is fitted to both the Lowlander 60 and 80. The precision machined castings house heat treated components which are kept perfectly aligned. Internal gear-sets are unique to Bunning and ensure that auger speeds are optimised to achieve excellent spread patterns

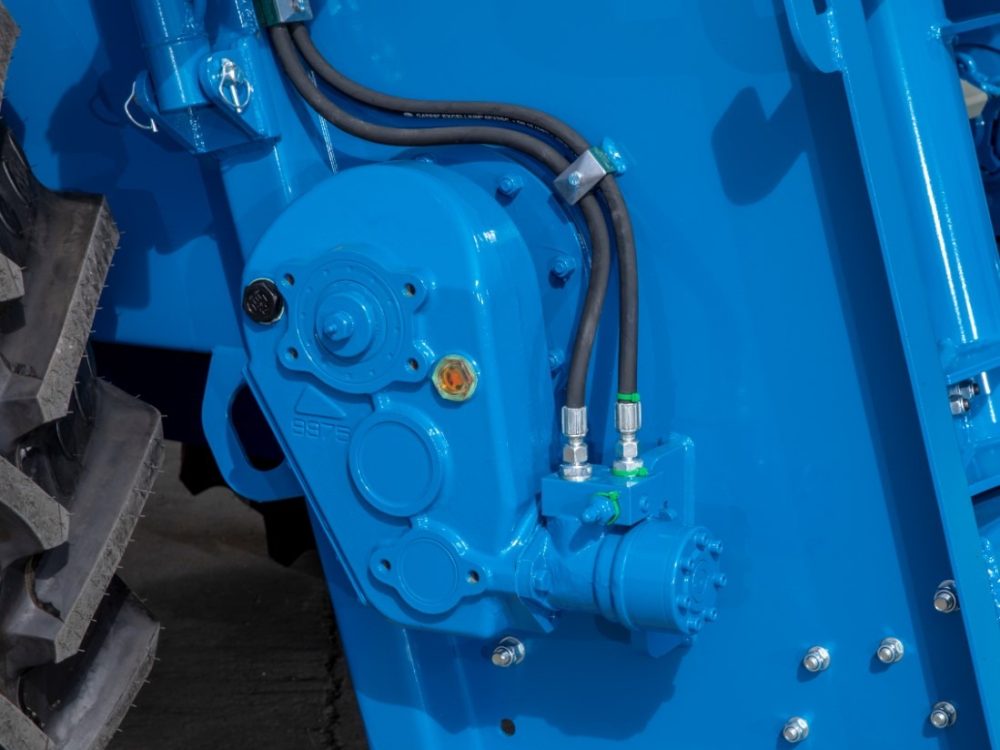

The 350 series floor drive gearbox is hydraulically driven to ensure an even feed of material to the spreading mechanism at all times. With a reverse feature, any foreign object too large to pass through the beaters can be easily removed. An adjustable cross-line relief valve also delivers additional protectio

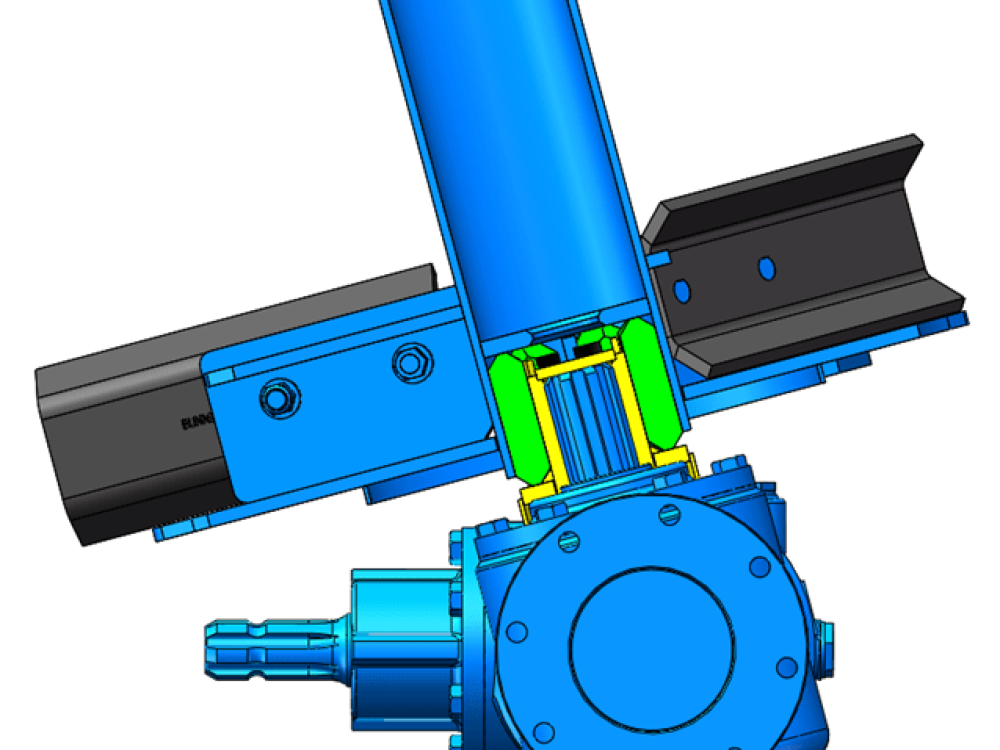

Especially developed to reduce shock loads to the auger drive gearbox, the rubber cushion arrangement located between the output shaft of the auger gearbox and the base of the auger contributes to the reliability and longevity of the machine

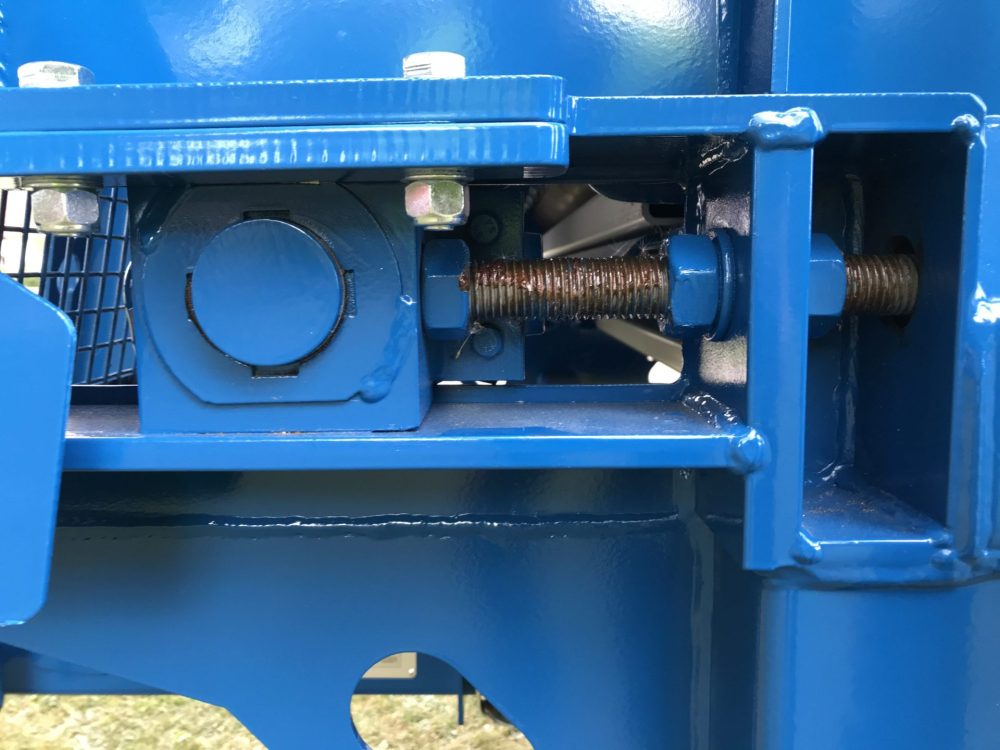

A robust, simple and reliable floor tensioning system allows easy adjustment ensuring that chains are kept to their optimum setting. The chains are visible from outside the machine making it easy to judge when tensioning is required. 50 mm high tensile shafts are used

50mm floor drive shafts rotate through polyester re-inforced composite bushes that contain a solid graphite filler, chosen for their high load applications in a variety of environments they are greasable, further extending their life

Machines fitted with slurry doors have Automatic Light Covers as standard. A simple mechanism triggered by the slurry door, moves the light cover over the lights as the slurry door begins to open

An extremely strong design and construction ensures that the door can be used as a grading device for light applications of materials as well as a device for retaining very runny products

The wide angle joint allows for turning on headlands with the PTO still engaged. It should be noted that the manufacturers recommend that you do not turn with the PTO under load

For increased capacity bolt on 240mm steel extension sides can be added. Spreader design load capacity should be checked relative to the density of the material to be carried

The in-cab electric remote floor speed control allows the operator to make adjustments to the floor speed while on the move

This options allows the operator to monitor door opening positions in relation to application rates

Designed for use when spreading low applications of products like Lime and chicken litter, the canopy ensures that all material is spread by the bottom auger blades

A choice of either 2 Line Air Only Brakes or Dual Supply (2 Line Air and Hydraulic) Brakes

To help clean out the deck area around the bottom of the augers these covers can be opened to allow material and water to flow out

A robust item designed with a sloping lid to reduce the build up of material

These ultra bright LED flashing/strobe lights are fitted as a pair and give a highly visible warning

Option to fit a swivel pick-up eye in lieu of fixed eye is available

Option to fit a 80mm Scharmuller spoon attachment in lieu of fixed eye is available

To enable the machine to be used for other jobs the auger assembly can be removed for the faster unloading of products such as grass, maize silage and even grain

Mudguards reduce spray and debris from tyres and give a width indication to traffic

These bright LED marker lights are fitted to the front & rear of the mudguards and give a positive marker to the overall width of the machine

Standard wheel is a 420/85 R34 8 stud.

Options: 480/70 R34 8 stud or 520/70 R34 8 stud

The Topcon Apollo spreader controller has all the features for today’s farming techniques. The standalone ISOCAN screen enables independent control of spreader with only 12 Volt power required from tractor

The Topcon Apollo spreader controller has all the features for today’s farming techniques. The standalone ISOCAN screen enables independent control of spreader with only 12 Volt power required from tractor

The GT 400 not only displays the live weight in the machine but also allows the operator to add the total weight up by pressing the start/stop button after every load. This simple weigh unit can be fitted through the whole range of Bunning muck spreaders from the 60 to the mammoth 380HD. The system is integrated with the same 20 tonne load cells as used on the popular and proven Topcon Apollo systems

As an option the machine can be manufactured to take weigh cells at a future date. The dummy weigh cells can be easily removed and replaced with full weigh cells.

Spreaders with a weigh cell system can have an overload beacon fitted. This helps operators loading the spreader know when a desired weight has been achieved to reduce chance of overloading. Beacon is magnetic and can be moved to improve visibility

While Bunning Blue or Bunning Green are our standard colours. From a BS or RAL number we can paint your machine in almost any colour