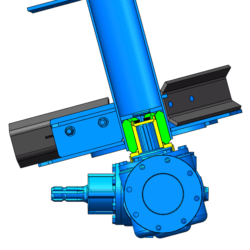

Twin 865mm diameter dynamically balanced vertical augers have flights laser cut from heat treated BORON steel to improve strength and service life. 20mm thick reversible hardened cutters manufactured using BORON steel are bolted and supported along back edge, shred products leaving a wide and even spread. Two fixed position BORON steel bottom blades per auger give wider spread widths of materials that are either fine or wet