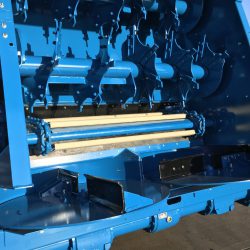

Twin 695mm dynamically balanced horizontal beaters have laser cut 10mm heat treated BORON steel flighting to improve strength and service life. Reversible hardened cutters manufactured using BORON steel are bolted and supported along the back edge, shred products giving an even and consistent feed on to the spinning discs