The Lowlander Widebody 380HD HBD

A product of GT Bunning, is rapidly gaining traction in the Australian agricultural sector. Renowned for its proficiency in chicken manure application, this spreader is increasingly favoured by discerning farmers.

We are thrilled to unveil our latest innovation, the ICS Upgrade, which revolutionises the performance of our renowned 4B8 Spinner System. With extensive research and development combined with rigorous spread testing, we are proud to announce that this package has exceeded all expectations, achieving exceptional results in the field.

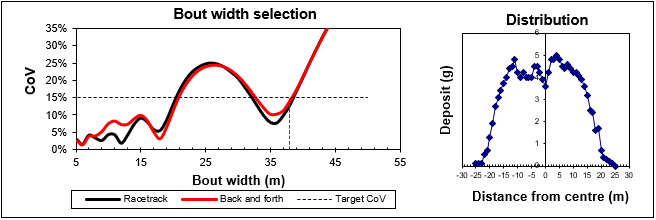

The key to the ICS upgrade’s success lies in the meticulously revised spinner vanes, carefully engineered to deliver unparalleled spreading efficiency. Through countless hours of testing and fine-tuning, we have optimised the design to ensure a uniform and accurate spread pattern, even at extended distances. As a result, our 4B8 Spinner System with the ICS Upgrade now offers an impressive spread range of 36 to 39 metres for urea applications.

To ensure the utmost precision and reliability, we have put the ICS Upgrade through its paces with over 20 spreaders, subjecting them to a comprehensive accreditation process. The results speak for themselves: each spreader has achieved accreditation for a 36-metre spread pattern, with application rates ranging from 50 to 400 kilograms. This extensive testing and accreditation provide you with confidence and peace of mind that our spreaders deliver optimal performance, regardless of the application requirements.

The new ICS Spinner Upgrade stands out from the crowd with its innovative features and advanced engineering, setting a new standard for precision spreading. At the heart of this upgrade are the state-of-the-art spinner vanes, meticulously redesigned to optimise spreading efficiency. These new vanes ensure a consistent and accurate spread pattern, resulting in optimal fertiliser distribution across the field.

To further enhance performance, the spinner disc has undergone a significant transformation. Now, CNC-pressed and welded with utmost precision, it offers more accurate angles for improved spreading accuracy. This meticulous manufacturing process guarantees that each spinner disc meets exact specifications, contributing to a more reliable and uniform spread pattern.

One notable advantage of the ICS Spinner Upgrade is its versatility. With the ability to reverse the spinner rotation, users gain greater control over product control. This feature proves invaluable when faced with challenging fertilisers and manures. By simply adjusting the spinner rotation, operators can adapt to different spreading conditions, ensuring consistent and efficient fertiliser distribution in any situation.

The combination of the redesigned vanes, the CNC-pressed and welded spinner disc, and the ability to reverse spinner rotation sets the ICS Spinner Upgrade apart. Landaco Spreaders remains committed to pushing the boundaries of innovation and delivering solutions that empower farmers to achieve optimal results.

Q: Can I upgrade my older Landaco Spreader with the ICS Spinners?

A: Yes, Landaco offers the ICS Spinner Upgrade as a complete kit or a simple bolt on solution for all Landaco Spreaders*.

Q: Is The ICS Spinner System easy to use?

A: Yes, Through the trials of spread testing and in crop tests Landaco has found the new upgrade has been extremely reliable and forgiving.

Q: Can you provide examples of the spread range achieved with the New ICS Spinner Upgrade?

A: An example of the spread patterns achievable with the new ICS system is displayed above. If you need additional examples, contact Landaco.

Landaco Spreaders’ introduction of the ICS Spinner Upgrade represents a significant advancement in precision spreading technology. This upgrade improves spreading efficiency, precision, and versatility with its redesigned spinner vanes, CNC-pressed and welded spinner disc, and the ability to reverse spinner rotation. It provides a reliable spread pattern of 36 metres with application rates ranging from 50 to 400 kilograms and has been tested and approved on over 20 spreaders.

By opting for the new ICS Spinner Upgrade, farmers can embrace the future of precise and efficient fertiliser distribution, guaranteeing optimal results from spreading operations. Upgrade your Landaco spreader immediately to unlock the full potential of this innovative technology.

Learn More about the T100 Trailing Spreader

Learn More about the Landaco T110 VR

Learn More about the Landaco Maxispread T160S Tandem

Learn More about the Landaco Maxispread T260S Tandem

A product of GT Bunning, is rapidly gaining traction in the Australian agricultural sector. Renowned for its proficiency in chicken manure application, this spreader is increasingly favoured by discerning farmers.

Unlock the secrets to maintaining your trailing spreader with our comprehensive guide. Aussie farmers, keep your essential equipment in peak condition, contributing to correct operation for optimal crop nutrient distribution every season. Dive in for expert tips and ensure your farming operations run seamlessly.

ICS Spinner System Upgrade Introducing the ICS Upgrade to the 4B8 Spinner System: Taking Landaco Spreaders to New Heights We are thrilled to unveil our

Variable Rate Spreading Variable Rate Spreading with a Landaco Spreader The agriculture industry has come a long way from traditional farming methods. With technological advancements,